Greener Eynsford Blog

Green news and views relevant to our community

Solar Panels - A Resident's View

23rd March 2023

Thank you to a resident of Eynsford who has provided details of their experience of having solar panels fitted.

Our experience of having a solar system fitted to our house in Pollyhaugh began back in June 2022. We received a communication from Kent County Council about a countywide scheme to promote the fitting of solar panels. The scheme was called Kent Solar Together and the idea was to have people register their interest and then invite companies to tender for the work. It was expected that this would result in reductions in the cost of the solar panels compared to what people would have to pay if they arranged for the installations themselves.

We had been thinking about having solar panels fitted for some time and were attracted by the scheme, not just because of the cost savings but also because of the assurance that participating in a council-backed scheme would give us that we would be contracting with a reputable supplier.

The company that fitted our panels was Home Smart Energy, who are based in Burgess Hill, West Sussex. We received an email from the company a few weeks after registering our interest asking us to confirm that we would like to proceed and to provide them with some information about the house, including photos and direction of the roof areas and a photo of the fuse board and whether there was any spare capacity within it. We subsequently received details of the proposed layout of panels to be fitted, along with an estimate of the cost.

Having accepted the estimate we paid a deposit for a surveyor to call and carry out an on-site survey of the property and finalise the installation. Based on this survey we had to delete one of the panels as it would be too close to one of our dormer windows. So the full system would consist of 7 500W panels, an inverter, battery storage, and a system that would, in the event of a power cut supply power to 2 sockets fitted above the inverter from which we could run extension leads to low power appliances in the event of a grid power outage, eg TV, table lamps, hob.

We didn’t hear from the company for a long time after the surveyor’s visit in mid-July but eventually, they contacted us to let us know that our panels etc would be fitted on Monday 12th December and that scaffolders would visit the week before. The scaffolding was erected as planned but unfortunately, the weather intervened with snow on 11th December and the installation had to be put back until the New Year.

The new installation date of 9th January finally came around and the whole system was installed in around 5 hours. The battery was 50% full when it was installed and it was a fairly sunny day so we could immediately see the cost of our electricity usage reducing from our smart meter.

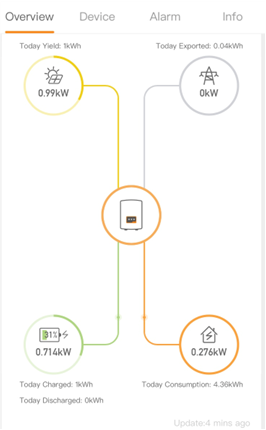

As with everything these days, there’s an app linked so the system (SolisCloud) through which we can see how much power the panels are producing, whether we are charging or discharging the battery, and whether we are exporting any power back to the grid. The app also shows our overall electricity usage and how much of that has come from our own generation. It also shows how much CO2 the system has saved and how many tree plantings that equates to. As of 12.00 on 25th Feb we have saved 159.52kg of CO2 emissions which sounds like a lot but it only equates to 0.09 trees!!

The data shown by the app is available both for the current day and for each of the days since the system has been installed so we are able to build up a picture of how our generation varies with the weather (in particular the level of cloud cover) and what our cost savings have been.

As of now the solar-produced energy has been just under 35% of our overall usage for the period since the panels were installed, and we estimate that we’ve saved £86.18 (£1.83 per day on average) which considering the time of year we are really pleased with. On the sunniest days we have generated up to 73.6% of our consumption! Unfortunately on some sunny days we have found ourselves exporting over 40% of our generation to the grid without being paid for it since the process of getting ourselves set up to receive payment from our supplier (EDF) under the Smart Export Guarantee scheme takes over 4 weeks. Even when we are set up the rate we’ll receive will be very low (only 5.6p per kWh) so we’ll be doing our best to time the usage of our electrical appliances so that we use the electricity that we generate rather than letting it go to the grid. Since we are on Economy 7 we generally try and run our higher-powered appliances when the much lower night rates apply but on the sunnier days we’ll run our dishwasher during the day using our own power!

Another thing that we try to do is to reduce spikes in our electricity consumption during the day (which tend to lead to us drawing from the grid) by using lower powered appliances. Eg a lower powered kettle will take a bit longer to boil but we can power it entirely from our own generation.

As you can see from the photo below the controls, battery and inverter for the system take up very little room and can easily be fitted, as here, in a small cupboard.

We’ve included a screenshot below of what the app looks like on a smartphone. From the data in the top right corner you can see that we weren’t using anything from the grid at the point that this screenshot was taken.

Biogas Powerplant

25th August 2022

The Darenth Valley’s Biogas Powerplant

by Erica Russell on behalf of the Green Team

Visiting a large scale anaerobic digestor is not a usual agenda item for the Parish green team but we were all curious to find out more about the ‘mini powerplant’ that has been built near Horton Kirby. Firstly, what is it?! This particular powerplant is driven by anaerobic digestion. This process relies on bacteria and microbes to break down plant material to create biogas, which in turn can be treated to allow the gas to be used for heating and cooking or to produce electricity. The process also creates biofertilizer than can go back onto the land. Across the UK anaerobic digestors recycle 2.5m tonnes of food waste each year.

The site is large, much bigger than any of us had expected. Oncoland Energy have spent over £10m on the plant and it’s run by a full-time manager and two staff. Initially designed to help spread the risk of fluctuating crop prices the digestor is also helping manage difficult agricultural waste, some of which produces large amounts of atmosphere warming gas – methane. Many of us in Eynsford will be familiar with at least one of the feedstocks used by the digestor – slurry from Bower Lane Farm! But, the site also takes in a lot of waste parts of crops, unwanted/oversized produce, including and rather surprisingly waste pomegranate skins. Carl explained that the site is working hard to develop relationships with local food processors to take on similar materials. The farm also grows some crops themselves to balance the nutrients within the digestor.

Digestor is a good description when thinking about how the process works – the feedstock is mashed and chopped up in a large machine (the mouth), fed into ‘the stomach’ through pipes, with biogas drawn off from the large digestors and then the odourless biofertilizer ‘waste’ is moved out into storage bays, before being used by local farms – very little is wasted.

Treating the biogas is complex and heavily regulated but the site is now producing enough back to the gas network to heat 2500 homes. The plant also has a small generator which, fuelled by biogas is putting electricity into the grid – about enough to light around 600 homes a year.

It was a fascinating visit, and we must give huge thanks to Carl Woolley, the site manager, who gave up his evening to show us around and explain the process.

We came, we repaired, we raised money!

16th June 2022

On Saturday 21st May, Eynsford's Green Team ran their first-ever Repair Cafe at Eynsford Village Hall!

Volunteers had been recruited from the local community to help with repairs including IT, bikes and textiles.

Unfortunately, our hoover repair man was unable to attend at the last minute, so other volunteers 'had a go' instead!

We sold some lovely tea and cake to people waiting for their turn. Visitors were encouraged to make a donation to the new village hall fund http://eynsfordvh.com/wp/how-t... and £150 was raised!

We hope to run the repair cafe again in the autumn and would love to recruit a few more volunteers to give up a few hours to help people to repair their stuff.

Thank you to Chris Lewington for the fab photos.